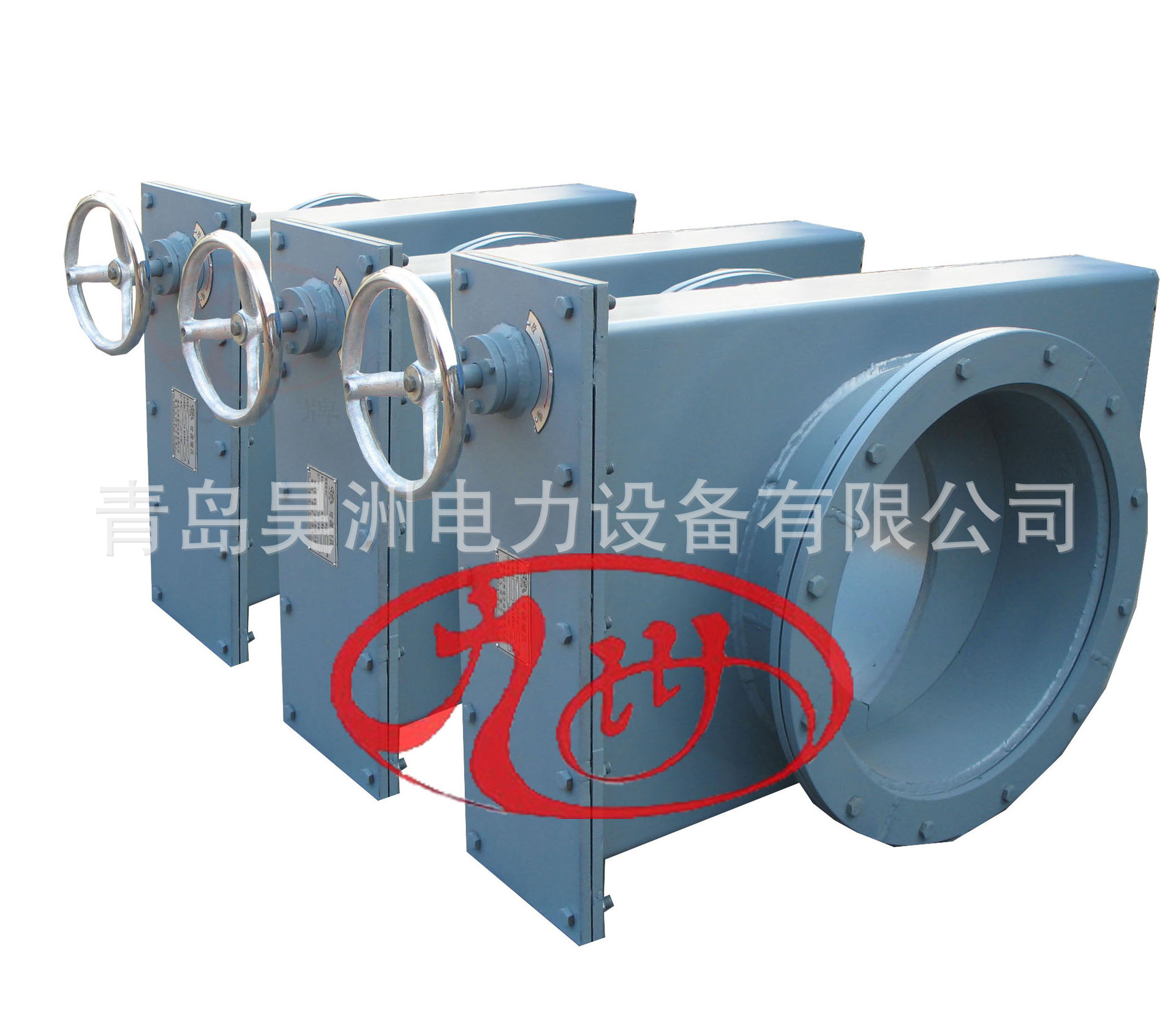

特点:

1.采用可调缩孔板,双芯板从管道中心向外往复运动,调节开启面积。管道内的煤粉始终是在管道中心流动,解决了第二代可调缩孔的煤粉偏心流动的缺点,减少了流动损失,避免管壁磨损过快,从而延长送粉管道的使用寿命。

2、设计有密封装置,煤粉始终不能串入缩孔内部,所以能始终保持启闭灵活的状态,使用寿命长。

3、设计有调节开度的刻度盘、指示针,刻度盘表示出截面积调节的百分比以及行程,调节十分方便、直观。

4、双芯板及耐磨通道简体采用稀土耐磨钢制造,耐磨性优越,密封性能好,启动灵活,调节性能好,外形美观,工艺精细。

Features:

1.

Using adjustable shrinkage plate, double-core plate from the center of

the pipeline reciprocating motion, adjust the opening area. The

pulverized coal in the pipeline always flows in the center of the

pipeline, which solves the disadvantages of the second generation of

adjustable shrinkage pulverized coal eccentric flow, reduces the flow

loss and avoids excessive wear of the tube wall, thereby prolonging the

service life of the powder feeding pipeline.

2, the design of a

sealing device, pulverized coal can not always string into the internal

shrinkage, it can always keep the state of flexible opening and

closing, long service life.

3, designed to adjust the opening of the

dial, indicating the dial, the dial shows the percentage of

cross-sectional area adjustment and travel, the adjustment is very

convenient and intuitive.

4, Double-core plate and wear-resistant

channel Simplified use of rare earth wear-resistant steel, superior

wear resistance, sealing performance, start flexible, good regulation

performance, beautiful appearance, fine technology.

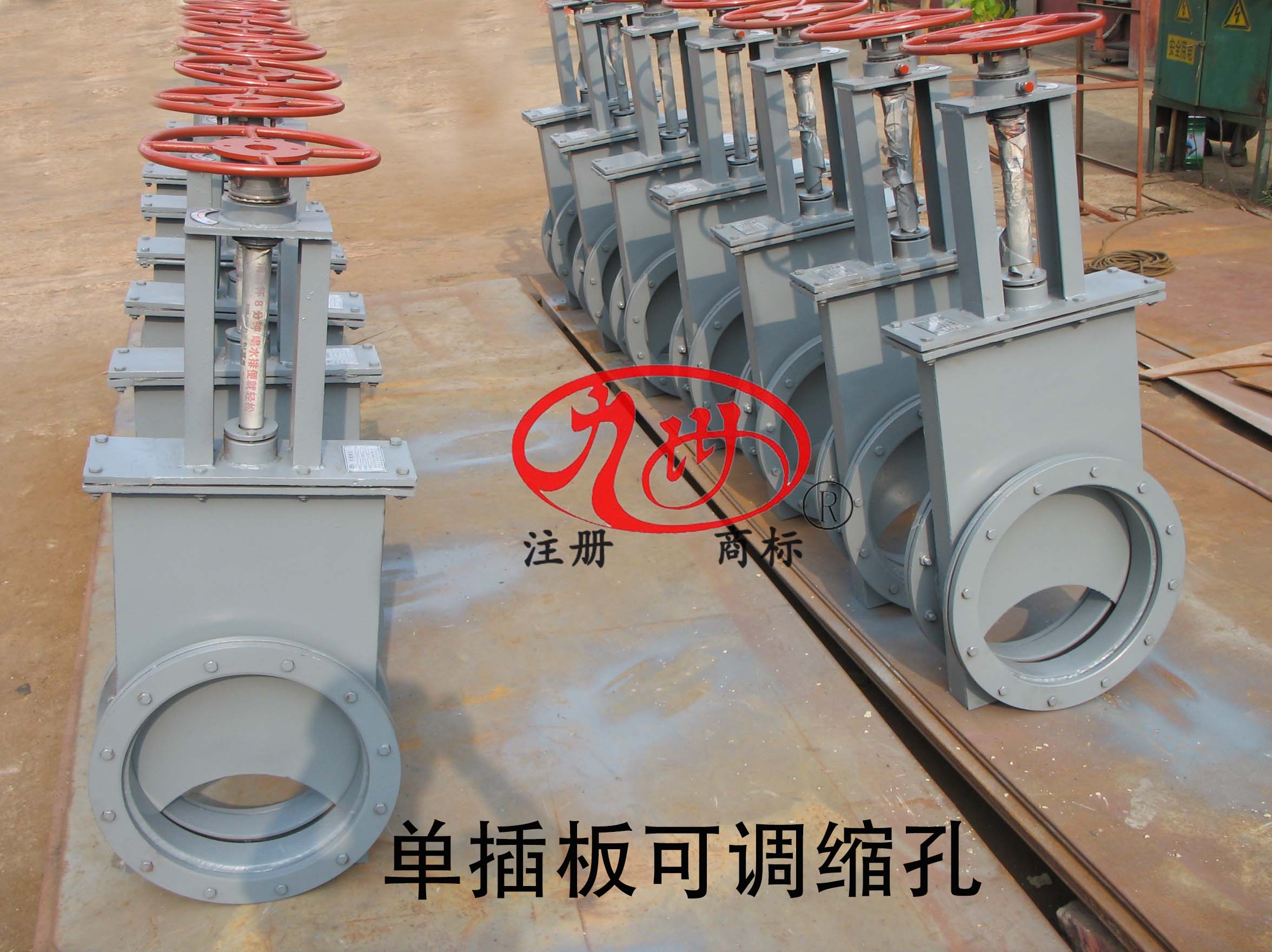

本缩孔现管道采用法兰连接,现管道法兰连接时用石棉橡胶垫密封。

安装前应先清理连接密封面,不允许有杂物影响密封性能。

手轮顺时针方向旋转为关闭方向。

本缩孔易磨损件是闸板。挡闸板磨损失效时,只需更换闸板,即可正常使用

-

胶球清洗装置,胶球泵,全自动滤水器

客服1

客服1